721 Catalog

Jump to …

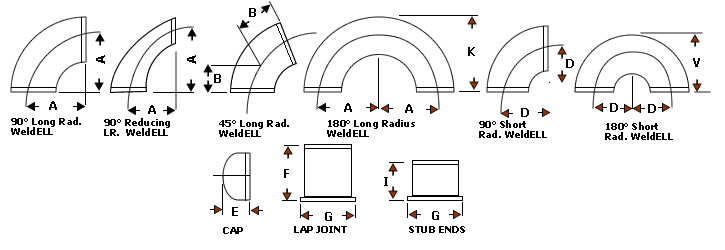

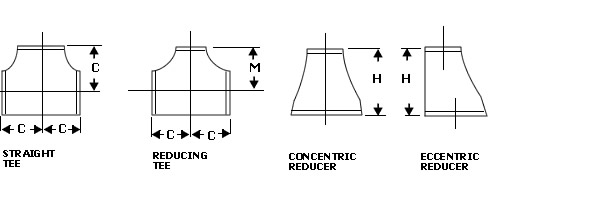

- Welding Fittings – Dimensions

- Welding Fittings – Weights

- Pipe Dimensions and Weights

- Material Specifications – Fittings

Welding Fittings – Dimensions

| NOM. PIPE SIZE | Out-SIDE DIAM | WeldELL | CAPS | STUB ENDS (See Note Below) | NOM PIPE SIZE | |||||||||

| A | B | D | K | V | E | G O.D. of Lap | Type A | Type B, C† | ||||||

| F (Length) | I (Length) | Corner Radius | I (Length) | Corner Radius | ||||||||||

| ANSI Std. | MSS Std. | MSS Std. | ||||||||||||

| ½ | .840 | 1 ½ | 5/8 | 1 7/8 | 1 | 1 3/8 | 3 | 2 | 1/8 | 2 | 1/32 | ½ | ||

| ¾ | 1.050 | 1 ½ | 1 11/16 | 1 | 1 11/16 | 3 | 2 | 1/8 | 2 | 1/32 | ¾ | |||

| 1 | 1.315 | 1 ½ | 7/8 | 1 | 2 3/16 | 1 5/8 | 1 ½ | 2 | 4 | 2 | 1/8 | 2 | 1/32 | 1 |

| 1 ¼ | 1.660 | 1 7/8 | 1 | 1 ¼ | 2 ¾ | 2 1/16 | 1 ½ | 2 ½ | 4 | 2 | 3/16 | 2 | 1/32 | 1 ¼ |

| 1 ½ | 1.900 | 2 ¼ | 1 1/8 | 1 ½ | 3 ¼ | 2 7/16 | 1 ½ | 2 7/8 | 4 | 2 | ¼ | 2 | 1/32 | 1 ½ |

| 2 | 2.375 | 3 | 1 3/8 | 2 | 4 3/16 | 3 3/16 | 1 ½ | 3 5/8 | 6 | 2 ½ | 5/16 | 2 ½ | 1/32 | 2 |

| 2 ½ | 2.875 | 3 ¾ | 1 ¾ | 2 ½ | 5 3/16 | 3 15/16 | 1 ½ | 4 1/8 | 6 | 2 ½ | 5/16 | 2 ½ | 1/32 | 2 ½ |

| 3 | 3.500 | 4 ½ | 2 | 3 | 6 ¼ | 4 ¾ | 2 | 5 | 6 | 2 ½ | 3/8 | 2 ½ | 1/32 | 3 |

| 3 ½ | 4.000 | 5 ¼ | 2 ¼ | 3 ½ | 7 ¼ | 5 ½ | 2 ½ | 5 ½ | 6 | 3 | 3/8 | 3 | 1/32 | 3 ½ |

| 4 | 4.500 | 6 | 2 ½ | 4 | 8 ¼ | 6 ¼ | 2 ½ | 6 3/16 | 6 | 3 | 7/16 | 3 | 1/32 | 4 |

| 5 | 5.563 | 7 ½ | 3 1/8 | 5 | 10 5/16 | 7 ¾ | 3 | 7 5/16 | 8 | 3 | 7/16 | 3 | 1/16 | 5 |

| 6 | 6.625 | 9 | 3 ¾ | 6 | 12 5/16 | 9 5/16 | 3 ½ | 8 ½ | 8 | 3 ½ | ½ | 3 ½ | 1/16 | 6 |

| 8 | 8.625 | 12 | 5 | 8 | 16 5/16 | 12 5/16 | 4 | 10 5/8 | 8 | 4 | ½ | 4 | 1/16 | 8 |

| 10 | 10.750 | 15 | 6 ¼ | 10 | 20 3/8 | 15 3/8 | 5 | 12 ¾ | 10 | 5 | ½ | 5 | 1/16 | 10 |

| 12 | 12.750 | 18 | 7 ½ | 12 | 24 3/8 | 18 3/8 | 6 | 15 | 10 | 6 | ½ | 6 | 1/16 | 12 |

| 14 | 14.000 | 21 | 8 ¾ | 14 | 28 | 21 | 6 ½ | 16 ¼ | 12 | ½ | 14 | |||

| 16 | 16.000 | 24 | 10 | 16 | 32 | 24 | 7 | 18 ½ | 12 | ½ | 16 | |||

| 18 | 18.000 | 27 | 11 ¼ | 18 | 36 | 27 | 8 | 21 | 12 | ½ | 18 | |||

| 20 | 20.000 | 30 | 12 ½ | 20 | 40 | 30 | 9 | 23 | 12 | ½ | 20 | |||

| 24 | 24.000 | 36 | 15 | 24 | 48 | 26 | 10 ½ | 27 ½ | 12 | ½ | 24 | |||

| 30 | 30.000 | 45 | 18 1/2 | 30 | 60 | 45 | 10 ½ | 30 | ||||||

Notes Continued:

Fittings having wall thicknesses of 0.065” are furnished with square ends unless otherwise specified.

Stub Ends:

Type A for use with Lap Joint Flanges.

Type B and C use with Slip-On-Flanges.

Types A and B are furnished with square inside corner, gasket surfaces machined and minimum lap thickness equal to nominal wall of barrel.

†Dimensions of Type C are the same as tabulated for Type B in 5S and 10S thicknesses. Type C is not available in 40S thicknesses. Type C has no fixed corner radius, lap face is not machined. Type C is only available in MSS length. Type B, usually purchased in the MSS length is also available in the ANSI length in Schedules 10S and 40S

| NOM PIPE SIZE | OUTLET | C | M | H | NOM PIPE SIZE | OUTLET | C | M | H | NOM PIPE SIZE | OUTLET | C | M | H | NOM PIPE SIZE | OUTLET | C | M | H |

| 3/4 | 3/4 | 1 1/8 | 3 1/2 | 3 ½ | 3 ¾ | 10 | 10 | 8 ½ | 20 | 20 | 15 | ||||||||

| 1/2 | 1 1/8 | 1 1/8 | 1 1/2 | 3 | 3 ¾ | 3 5/8 | 4 | 8 | 8 ½ | 8 | 7 | 18 | 15 | 14 ½ | 20 | ||||

| 1 | 1 | 1 1/2 | 2 ½ | 3 ¾ | 3 ½ | 4 | 6 | 8 ½ | 7 5/8 | 7 | 16 | 15 | 14 | 20 | |||||

| 3/4 | 1 1/2 | 1 1/2 | 2 | 2 | 3 ¾ | 3 ¼ | 4 | 5 | 8 ½ | 7 ½ | 7 | 14 | 15 | 14 | 20 | ||||

| 1/2 | 1 1/2 | 1 1/2 | 2 | 1 ½ | 3 ¾ | 3 1/8 | 4 | 4 | 8 ½ | 7 ¼ | 7 | 15 | 13 5/8 | 20 | |||||

| 1 1/4 | 1 ¼ | 1 7/8 | 4 | 4 | 4 1/8 | 12 | 12 | 10 | 10 | 15 | 13 1/8 | 20 | |||||||

| 1 | 1 7/8 | 1 7/8 | 2 | 3 ½ | 4 1/8 | 4 | 4 | 10 | 10 | 9 ½ | 8 | 8 | 15 | 12 ¾ | 20 | ||||

| ¾ | 1 7/8 | 1 7/8 | 2 | 3 | 4 1/8 | 3 7/8 | 4 | 8 | 10 | 9 | 8 | 24 | 24 | 17 | |||||

| 1/2 | 1 7/8 | 1 7/8 | 2 | 2 ½ | 4 1/8 | 3 ¾ | 4 | 6 | 10 | 8 5/8 | 8 | 20 | 17 | 17 | 20 | ||||

| 1 1/2 | 1 ½ | 2 ¼ | 2 | 4 1/8 | 3 ½ | 4 | 5 | 10 | 8 ½ | 8 | 18 | 17 | 16 ½ | 20 | |||||

| 1 ¼ | 2 ¼ | 2 ¼ | 2 ½ | 1 ½ | 4 1/8 | 3 3/8 | 4 | 14 | 14 | 11 | 16 | 17 | 16 | 20 | |||||

| 1 | 2 ¼ | 2 ¼ | 2 ½ | 5 | 5 | 4 7/8 | 12 | 11 | 10 5/8 | 14 | 17 | 16 | 20 | ||||||

| ¾ | 2 ¼ | 2 ¼ | 2 ½ | 4 | 4 7/8 | 4 5/8 | 5 | 10 | 11 | 10 1/8 | 12 | 17 | 15 5/8 | 20 | |||||

| ½ | 2 ¼ | 2 ¼ | 2 ½ | 3 ½ | 4 7/8 | 4 ½ | 5 | 8 | 11 | 9 ¾ | 10 | 17 | 15 1/8 | 20 | |||||

| 2 | 2 | 2 ½ | 3 | 4 7/8 | 4 3/8 | 5 | 6 | 11 | 9 3/8 | 30 | 30 | 22 | |||||||

| 1 ½ | 2 ½ | 2 3/8 | 3 | 2 ½ | 4 7/8 | 4 ¼ | 5 | 16 | 16 | 12 | 24 | 22 | 21 | 24 | |||||

| 1 ¼ | 2 ½ | 2 ¼ | 3 | 2 | 4 7/8 | 4 1/8 | 5 | 14 | 12 | 12 | 14 | 20 | 22 | 20 | 24 | ||||

| 1 | 2 ½ | 2 | 3 | 6 | 6 | 5 5/8 | 12 | 12 | 11 5/8 | 14 | 18 | 22 | 19 ½ | 24 | |||||

| ¾ | 2 ½ | 1 ¾ | 3 | 5 | 5 5/8 | 5 3/8 | 5 ½ | 10 | 12 | 11 1/8 | 14 | 16 | 22 | 19 | 24 | ||||

| 2 1/2 | 2 ½ | 3 | 4 | 5 5/8 | 5 1/8 | 5 ½ | 8 | 12 | 10 ¾ | 14 | 14 | 22 | 19 | 24 | |||||

| 2 | 3 | 2 ¾ | 3 ½ | 3 ½ | 5 5/8 | 5 | 5 ½ | 6 | 12 | 10 3/8 | 14 | 36 | 36 | 26 ½ | |||||

| 1 ½ | 3 | 2 5/8 | 3 ½ | 3 | 5 5/8 | 4 7/8 | 5 ½ | 18 | 18 | 13 ½ | 30 | 26 ½ | 25 | 24 | |||||

| 1 ¼ | 3 | 2 ½ | 3 ½ | 2 ½ | 5 5/8 | 4 ¾ | 5 ½ | 16 | 13 ½ | 13 | 15 | 24 | 26 ½ | 24 | 24 | ||||

| 1 | 3 | 2 ¼ | 3 ½ | 8 | 8 | 7 | 14 | 13 ½ | 13 | 15 | 20 | 26 ½ | 23 | 24 | |||||

| 3 | 3 | 3 3/8 | 6 | 7 | 6 5/8 | 6 | 12 | 13 ½ | 12 5/8 | 15 | 18 | 26 ½ | 22 ½ | 24 | |||||

| 2 ½ | 3 3/8 | 3 ¼ | 3 ½ | 5 | 7 | 6 3/8 | 6 | 10 | 13 ½ | 12 1/8 | 15 | 16 | 26 ½ | 22 | 24 | ||||

| 2 | 3 3/8 | 3 | 3 ½ | 4 | 7 | 6 1/8 | 6 | 8 | 13 ½ | 11 ¾ | 15 | 42 | 42 | 30 | |||||

| 1 ½ | 3 3/8 | 2 7/8 | 3 ½ | 3 ½ | 7 | 6 | 6 | 36 | 30 | 28 | 24 | ||||||||

| 1 1/4 | 3 3/8 | 2 ¾ | 3 ½ | 30 | 30 | 28 | 24 | ||||||||||||

| 24 | 30 | 26 | 24 | ||||||||||||||||

| 20 | 30 | 26 | 24 |

Welding Fittings – Weights

Approximate Weight Each – Pounds.

| NOM PIPE SIZE | 90° WeldELLS – Long Radius | ||||

| Pipe Schedule | |||||

| 5S | 10S | 40S | 80S | 160 | |

| ½ | .10 | .13 | .17 | .22 | |

| ¾ | .10 | .13 | .17 | .23 | |

| 1 | .18 | .29 | .34 | .45 | .59 |

| 1 ¼ | .25 | .47 | .58 | .77 | .97 |

| 1 ½ | .36 | .64 | .84 | 1.12 | 1.50 |

| 2 | .62 | 1.09 | 1.50 | 2.07 | 2.96 |

| 2 ½ | 1.21 | 1.82 | 2.98 | 3.95 | 5.17 |

| 3 | 1.74 | 2.68 | 4.68 | 6.33 | 8.84 |

| 3 ½ | 2.33 | 3.59 | 6.56 | 9.04 | |

| 4 | 3.01 | 4.62 | 8.90 | 12.4 | 18.6 |

| 5 | 6.10 | 8.00 | 15.10 | 21.4 | 34.0 |

| 6 | 8.95 | 11.50 | 23.50 | 35.3 | 56.0 |

| 8 | 15.4 | 2.2 | 47.0 | 71.0 | 123.0 |

| 10 | 29.2 | 38.6 | 83.0 | 110.0 | 238.0 |

| 12 | 52.0 | 59.5 | 123.0 | 160.0 | 397.0 |

| 14 | 66.0 | 80.0 | 158.0 | 208.0 | 546.0 |

| 16 | 90.0 | 105.0 | 207.0 | 273.0 | 809.0 |

| 18 | 114.0 | 130.0 | 263.0 | 347.0 | |

| 20 | 159.0 | 185.0 | 323.0 | 428.0 | |

| 24 | 260.0 | 314.0 | 468.0 | 622.0 | |

| 30 | 475.0 | 612.0 | 733.0 | 972.0 | |

| NOM PIPE SIZE | 90° WeldELLS – Short Radius | ||||

| Pipe Schedule | |||||

| 5S | 10S | 40S | 80S | 160 | |

| ½ | |||||

| ¾ | |||||

| 1 | .16 | .18 | .23 | .41 | .48 |

| 1 ¼ | .22 | .30 | .39 | .64 | .74 |

| 1 ½ | .30 | .42 | .56 | .75 | 1.00 |

| 2 | .46 | .70 | 1.00 | 1.38 | 2.00 |

| 2 ½ | .93 | 1.2 | 1.98 | 2.64 | 3.5 |

| 3 | 1.22 | 1.7 | 3.12 | 4.22 | 5.9 |

| 3 ½ | 1.62 | 2.3 | 4.38 | 6.04 | |

| 4 | 2.1 | 3.0 | 5.9 | 8.25 | 12.5 |

| 5 | 4.2 | 5.2 | 10.1 | 14.30 | 23.0 |

| 6 | 6.3 | 8.2 | 15.6 | 23.50 | 37.5 |

| 8 | 10.5 | 14.2 | 31.4 | 47.7 | 82.0 |

| 10 | 20.0 | 25.0 | 55.7 | 75.2 | 159.0 |

| 12 | 34.0 | 39.0 | 81.9 | 108.0 | 265.0 |

| 14 | 43.0 | 52.0 | 105.0 | 139.0 | 365.0 |

| 16 | 60.0 | 68.0 | 138.0 | 182.0 | 540.0 |

| 18 | 77.0 | 86.0 | 175.0 | 231.0 | |

| 20 | 106.0 | 122.0 | 215.0 | 286.0 | |

| 24 | 178.0 | 203.0 | 313.0 | 415.0 | |

| 30 | 320.0 | 390.0 | 488.0 | 649.0 | |

| NOM PIPE SIZE | 45° WeldELLS | ||||

| Pipe Schedule | |||||

| 5S | 10S | 40S | 80S | 160 | |

| ½ | .05 | .07 | .09 | .11 | |

| ¾ | .05 | .07 | .09 | .11 | |

| 1 | .12 | .14 | .17 | .22 | .29 |

| 1 ¼ | .16 | .23 | .29 | .39 | .49 |

| 1 ½ | .22 | .32 | .42 | .56 | .75 |

| 2 | .34 | .54 | .75 | 1.04 | 1.48 |

| 2 ½ | .68 | .91 | 1.49 | 1.98 | 2.59 |

| 3 | .90 | 1.34 | 2.34 | 3.17 | 4.42 |

| 3 ½ | 1.19 | 1.79 | 3.28 | 4.52 | |

| 4 | 1.51 | 2.31 | 4.45 | 6.20 | 9.30 |

| 5 | 3.09 | 4.00 | 7.55 | 10.70 | 17.00 |

| 6 | 4.48 | 5.75 | 11.80 | 17.70 | 28.00 |

| 8 | 7.70 | 11.1 | 23.5 | 35.8 | 61.0 |

| 10 | 14.70 | 19.3 | 41.8 | 56.0 | 119.0 |

| 12 | 26.10 | 29.8 | 61.5 | 81.0 | 199.0 |

| 14 | 32.0 | 40.0 | 79.0 | 104.0 | 273.0 |

| 16 | 45.0 | 51.0 | 104.0 | 137.0 | 405.0 |

| 18 | 57.0 | 64.0 | 132.0 | 174.0 | |

| 20 | 80.0 | 93.0 | 162.0 | 214.0 | |

| 24 | 130.0 | 157.0 | 234.0 | 311.0 | |

| 30 | 240.0 | 306.0 | 367.0 | 486.0 | |

| NOM PIPE SIZE | 180° Returns – Long Radius | ||||

| Pipe Schedule | |||||

| 5S | 10S | 40S | 80S | 160 | |

| ½ | .20 | .27 | .35 | .45 | |

| ¾ | .20 | .27 | .35 | .46 | |

| 1 | .38 | .58 | .69 | .89 | 1.77 |

| 1 ¼ | .50 | .93 | 1.17 | 1.54 | 1.94 |

| 1 ½ | .71 | 1.29 | 1.68 | 2.22 | 3.00 |

| 2 | 1.25 | 2.18 | 3.00 | 4.14 | 5.92 |

| 2 ½ | 2.42 | 3.64 | 5.96 | 7.90 | 10.30 |

| 3 | 3.49 | 5.36 | 9.36 | 12.70 | 17.70 |

| 3 ½ | 4.67 | 7.17 | 13.10 | 18.10 | |

| 4 | 6.02 | 9.24 | 17.80 | 24.80 | 37.20 |

| 5 | 12.20 | 16.00 | 30.20 | 42.80 | 68.00 |

| 6 | 17.89 | 23.00 | 47.00 | 70.60 | 112.00 |

| 8 | 30.8 | 44.3 | 94.0 | 145.0 | 246.0 |

| 10 | 58.4 | 77.0 | 165.0 | 225.0 | 476.0 |

| 12 | 104.0 | 119.0 | 245.0 | 325.0 | 794.0 |

| 14 | 132.0 | 160.0 | 316.0 | 416.0 | 1092.0 |

| 16 | 180.0 | 210.0 | 414.0 | 546.0 | 1618.0 |

| 18 | 228.0 | 260.0 | 526.0 | 694.0 | |

| 20 | 318.0 | 370.0 | 646.0 | 856.0 | |

| 24 | 520.0 | 628.0 | 936.0 | 1244.0 | |

| 30 | 950.0 | 1224.0 | 1466.0 | 1944.0 | |

| NOM PIPE SIZE | 180° Returns – Short Radius | ||||

| Pipe Schedule | |||||

| 5S | 10S | 40S | 80S | 160 | |

| ½ | |||||

| ¾ | |||||

| 1 | .32 | .36 | .46 | ||

| 1 ¼ | .44 | .60 | .78 | ||

| 1 ½ | .60 | .84 | 1.12 | 1.50 | 2.00 |

| 2 | .92 | 1.40 | 2.00 | 2.76 | 4.00 |

| 2 ½ | 1.86 | 2.40 | 3.96 | 5.28 | 7.00 |

| 3 | 2.44 | 3.40 | 6.24 | 8.44 | 11.80 |

| 3 ½ | 3.24 | 4.60 | 8.76 | 12.10 | |

| 4 | 4.2 | 6.0 | 11.9 | 16.5 | 25.0 |

| 5 | 8.4 | 10.4 | 20.2 | 28.6 | 46.0 |

| 6 | 12.6 | 16.4 | 31.2 | 47.0 | 75.0 |

| 8 | 21.0 | 28.4 | 63.0 | 95.0 | 164.0 |

| 10 | 40.0 | 50.0 | 111.0 | 150.0 | 318.0 |

| 12 | 68.0 | 78.0 | 164.0 | 216.0 | 530.0 |

| 14 | 86.0 | 104.0 | 210.0 | 278.0 | 730.0 |

| 16 | 120.0 | 136.0 | 276.0 | 364.0 | 1080.0 |

| 18 | 154.0 | 176.0 | 350.0 | 462.0 | |

| 20 | 212.0 | 244.0 | 430.0 | 572.0 | |

| 24 | 356.0 | 406.0 | 626.0 | 830.0 | |

| 30 | 640.0 | 780.0 | 976.0 | 1298.0 | |

| NOM PIPE SIZE | Tees- Straight & Reducing† | ||||

| Pipe Schedule | |||||

| 5S | 10S | 40S | 80S | 160 | |

| ½ | .20 | .23 | .30 | .36 | |

| ¾ | .25 | .30 | .47 | .55 | .58 |

| 1 | .46 | .55 | .60 | .73 | .92 |

| 1 ¼ | .83 | 1.15 | 1.10 | 1.35 | 1.61 |

| 1 ½ | 1.17 | 1.61 | 1.61 | 1.99 | 2.50 |

| 2 | 1.40 | 1.72 | 4.16 | 4.12 | 4.75 |

| 2 ½ | 2.00 | 2.87 | 6.35 | 6.78 | 7.10 |

| 3 | 3.22 | 3.82 | 8.41 | 9.92 | 13.00 |

| 3 ½ | 4.03 | 4.80 | 11.40 | 13.60 | |

| 4 | 4.62 | 5.80 | 13.2 | 18.6 | 31.5 |

| 5 | 8.30 | 10.30 | 21.9 | 28.5 | 48.5 |

| 6 | 11.96 | 14.60 | 34.6 | 42.5 | 75.0 |

| 8 | 17.6 | 24.0 | 61.0 | 76.0 | 131.0 |

| 10 | 35.1 | 40.0 | 89.0 | 115.0 | 235.0 |

| 12 | 51.5 | 56.0 | 145.0 | 185.0 | 350.0 |

| 14 | 54.0 | 60.0 | 180.0 | 260.0 | |

| 16 | 68.0 | 75.0 | 240.0 | 350.0 | |

| 18 | 82.0 | 95.0 | 310.0 | 375.0 | |

| 20 | 110.0 | 130.0 | 480.0 | 500.0 | |

| 24 | 175.0 | 200.0 | 550.0 | 650.0 | |

| 30 | 920.0 | 1050.0 | |||

| OM PIPE SIZE | Crosses – Straight & Reducing† | |||

| Pipe Schedule | ||||

| 5S | 10S | 40S | 80S | |

| ½ | ||||

| ¾ | ||||

| 1 | ||||

| 1 ¼ | .77 | 1.12 | 1.34 | 1.62 |

| 1 ½ | 1.25 | 1.63 | 1.99 | 2.43 |

| 2 | 1.44 | 2.04 | 2.93 | 3.69 |

| 2 ½ | 2.31 | 3.30 | 5.11 | 6.28 |

| 3 | 3.14 | 4.50 | 7.26 | 9.16 |

| 3 ½ | 4.00 | 5.73 | 9.70 | 12.45 |

| 4 | 4.91 | 6.00 | 12.5 | 16.1 |

| 5 | 9.01 | 11.30 | 19.4 | 25.7 |

| 6 | 12.95 | 15.60 | 28.7 | 39.9 |

| 8 | 20.6 | 27.6 | 52.0 | 74.0 |

| 10 | 37.7 | 46.4 | 88.0 | 115.0 |

| 12 | 64.5 | 70.4 | 125.0 | 160.0 |

| 14 | 68.0 | 80.0 | 150.0 | 195.0 |

| 16 | 80.0 | 92.0 | 198.0 | 245.0 |

| 18 | 105.0 | 115.0 | 250.0 | 320.0 |

| 20 | 145.0 | 163.0 | 310.0 | 400.0 |

| 24 | 225.0 | 240.0 | 450.0 | 575.0 |

| 30 | ||||

| NOM PIPE SIZE | Reducers – Conc. & Ecc. | ||||

| Pipe Schedule | |||||

| 5S | 10S | 40S | 80S | 160 | |

| ½ | |||||

| ¾ | .14 | .21 | .15 | .22 | .32 |

| 1 | .15 | .25 | .28 | .36 | .47 |

| 1 ¼ | .20 | .34 | .38 | .50 | .63 |

| 1 ½ | .23 | .38 | .57 | .76 | 1.01 |

| 2 | .34 | .58 | .90 | 1.25 | 1.86 |

| 2 ½ | .60 | .86 | 1.70 | 2.23 | 2.92 |

| 3 | .74 | 1.08 | 2.20 | 2.99 | 4.17 |

| 3 ½ | 1.00 | 1.43 | 3.00 | 4.16 | |

| 4 | 1.11 | 1.61 | 3.60 | 5.00 | 7.52 |

| 5 | 2.34 | 2.85 | 6.10 | 8.65 | 13.80 |

| 6 | 3.17 | 3.91 | 8.70 | 13.10 | 20.80 |

| 8 | 4.55 | 6.18 | 14.3 | 21.7 | 37.3 |

| 10 | 8.16 | 10.05 | 23.6 | 31.9 | 67.4 |

| 12 | 14.15 | 15.38 | 33.1 | 43.6 | 107.0 |

| 14 | 25.0 | 30.0 | 59.2 | 78.3 | |

| 16 | 31.0 | 34.0 | 73.0 | 97.0 | |

| 18 | 42.0 | 47.0 | 88.0 | 117.0 | |

| 20 | 70.0 | 86.0 | 131.0 | 174.0 | |

| 24 | 106.0 | 128.0 | 158.0 | 210.0 | |

| 30 | 237.0 | 315.0 | |||

| NOM PIPE SIZE | Welding Caps | ||||

| Pipe Schedule | |||||

| 5S | 10S | 40S | 80S | 160 | |

| ½ | .07 | .07 | .07 | .10 | |

| ¾ | .10 | .12 | .13 | .19 | |

| 1 | .10 | .16 | .22 | .28 | .40 |

| 1 ¼ | .13 | .22 | .31 | .40 | .50 |

| 1 ½ | .17 | .28 | .37 | .49 | .64 |

| 2 | .24 | .41 | .51 | .69 | 1.22 |

| 2 ½ | .37 | .53 | .81 | 1.03 | 1.85 |

| 3 | .58 | .83 | 1.42 | 1.88 | 3.25 |

| 3 ½ | .70 | 1.01 | 2.14 | 2.88 | |

| 4 | .88 | 1.26 | 2.54 | 3.47 | 6.25 |

| 5 | 1.97 | 2.43 | 4.19 | 5.84 | 10.50 |

| 6 | 2.53 | 3.11 | 6.44 | 9.45 | 16.30 |

| 8 | 4.02 | 5.46 | 11.20 | 16.70 | 31.50 |

| 10 | 8.07 | 9.95 | 20.00 | 26.50 | 55.50 |

| 12 | 13.49 | 14.72 | 29.50 | 38.00 | 92.00 |

| 14 | 14.8 | 17.7 | 35.4 | 45.3 | 125.0 |

| 16 | 19.7 | 22.4 | 44.8 | 57.8 | 180.0 |

| 18 | 25.2 | 29.0 | 57.2 | 74.0 | |

| 20 | 35.5 | 41.4 | 71.0 | 94.0 | |

| 24 | 59.5 | 68.0 | 102.0 | 131.0 | |

| 30 | 91.0 | 114.0 | 137.0 | 186.0 | |

| NOM PIPE SIZE | 45° Laterals | |

| Pipe Schedule | ||

| 40S | 10S | |

| ½ | ||

| ¾ | ||

| 1 | 1.71 | 2.52 |

| 1 ¼ | 2.44 | 3.86 |

| 1 ½ | 3.27 | 5.44 |

| 2 | 5.04 | 7.76 |

| 2 ½ | 9.23 | 13.50 |

| 3 | 12.60 | 18.80 |

| 3 ½ | 17.20 | 25.60 |

| 4 | 20.8 | 32.8 |

| 5 | 31.4 | 49.8 |

| 6 | 42.4 | 79.4 |

| 8 | 76.4 | 140.0 |

| 10 | 124.0 | 202.0 |

| 12 | 180.0 | 273.0 |

| 14 | 218.0 | 340.0 |

| 16 | 275.0 | 433.0 |

| 18 | 326.0 | 526.0 |

| 20 | 396.0 | 628.0 |

| 24 | 544.0 | 882.0 |

| 30 | ||

| NOM PIPE SIZE | Stub Ends – MSS Length | ||

| Pipe Schedule | |||

| 5S | 10S | 40S | |

| ½ | 0.13 | 0.17 | 0.25 |

| ¾ | 0.15 | 0.19 | 0.34 |

| 1 | 0.2 | 0.31 | 0.41 |

| 1 ¼ | 0.29 | 0.46 | 0.58 |

| 1 ½ | 0.35 | 0.55 | 0.83 |

| 2 | 0.54 | 0.83 | 1.19 |

| 2 ½ | 0.77 | 1.04 | 1.76 |

| 3 | 1.03 | 1.41 | 2.5 |

| 3 ½ | 1.33 | 1.84 | 3.25 |

| 4 | 1.57 | 2.16 | 4 |

| 5 | 2.31 | 2.73 | 5.6 |

| 6 | 3.58 | 4.3 | 8.2 |

| 8 | 5.4 | 6.85 | 13 |

| 10 | 8.91 | 10.73 | 23 |

| 12 | 14.57 | 15.69 | 33 |

| 14 | |||

| 16 | |||

| 18 | |||

| 20 | |||

| 24 | |||

| 30 | |||

| NOM PIPE SIZE | Stub Ends – ANSI Length (Formerly ASA) | ||||

| Pipe Schedule | |||||

| 5S | 10S | 40S | 80S | 160 | |

| ½ | 0.16 | 0.23 | 0.3 | 0.32 | |

| ¾ | 0.27 | 0.34 | 0.4 | 0.44 | |

| 1 | 0.34 | 0.54 | 0.66 | 0.85 | 1.13 |

| 1 ¼ | 0.47 | 0.76 | 0.91 | 1.21 | 1.51 |

| 1 ½ | 0.56 | 0.9 | 1.22 | 1.49 | 2.02 |

| 2 | 1 | 1.62 | 2.19 | 3.01 | 4.51 |

| 2 ½ | 1.49 | 2.1 | 3.45 | 4.59 | 6.02 |

| 3 | 1.91 | 2.67 | 4.71 | 6.27 | 8.8 |

| 3 ½ | 2.2 | 3.08 | 5.54 | 6.58 | |

| 4 | 2.55 | 3.56 | 6.7 | 9.33 | 14.1 |

| 5 | 4.96 | 6.07 | 11.7 | 16.6 | 26.4 |

| 6 | 6.42 | 7.79 | 15.2 | 23 | 36.4 |

| 8 | 8.7 | 11.8 | 23 | 35 | 60 |

| 10 | 15.24 | 18.5 | 40 | 53.6 | 113 |

| 12 | 21.96 | 23.9 | 49 | 65.8 | 160 |

| 14 | 64 | 89 | |||

| 16 | 72 | 96 | |||

| 18 | 85 | 112 | |||

| 20 | 94 | 125 | |||

| 24 | 113 | 151 | |||

| 30 | 0.16 | 0.23 | 0.3 | 0.32 | |

Note: Weights tabulated are for stainless steel welding fittings. For aluminum, multiply tabulated weights by 0.345.

†Approximat weight listed does not take into account variations depending on outlet size. Straight sizes will normally be slightly heavier and reducing sizes slightly lighter than listed.

Pipe Dimensions and Weights

| NOM.PIPE SIZE | OUTSIDE DIAM. INCHES | I.P.S. | SCHEDULE | WALL IN. | INSIDE DIAM. INCHES | WT/FT POUNDS |

| ½ | .840 | 5S | .065 | .710 | .5383 | |

| 10S | .083 | .674 | .6710 | |||

| 40 | 40S Std. | .109 | .622 | .8510 | ||

| 80 | 80S Ex. Hvy. | .147 | .546 | 1.088 | ||

| 160 | .188 | .466 | 1.309 | |||

| XX Hvy. | .294 | .252 | 1.714 | |||

| ¾ | 1.050 | 5S | .065 | .920 | .6838 | |

| 10S | .083 | .844 | ||||

| 40S Std. | .109 | .622 | .8510 | 1.131 | ||

| 80S Ex. Hvy. | .147 | .546 | 1.088 | 1.474 | ||

| 160 | .188 | .466 | 1.309 | 1.944 | ||

| XX Hvy. | .294 | .252 | .434 | 2.441 | ||

| 1 | 1.315 | 5S | .065 | 1.185 | .8678 | |

| 10S | .109 | 1.097 | 1.404 | |||

| 40 | 40S Std. | .133 | 1.049 | 1.679 | ||

| 80 | 80S Ex. Hvy. | .179 | .957 | 2.172 | ||

| 160 | .250 | .815 | 2.844 | |||

| XX Hvy. | .358 | .599 | 3.659 | |||

| 1 ¼ | 1.660 | 5S | .065 | 1.530 | 1.107 | |

| 10S | .109 | 1.442 | 1.806 | |||

| 40 | 40S Std. | .140 | 1.380 | 2.273 | ||

| 80 | 80S Ex. Hvy. | .191 | 1.278 | 2.997 | ||

| 160 | .250 | 1.160 | 3.765 | |||

| XX Hvy. | .382 | .896 | 5.214 | |||

| 1 ½ | 1.900 | 5S | .065 | 1.770 | 1.274 | |

| 10S | .109 | 1.682 | 2.085 | |||

| 40 | 40S Std. | .154 | 1.610 | 2.718 | ||

| 80 | 80S Ex. Hvy. | .200 | 1.500 | 3.631 | ||

| 160 | .281 | 1.338 | 4.859 | |||

| XX Hvy. | .400 | 1.100 | 6.408 | |||

| 2 | 2.375 | 5S | .065 | 2.245 | 1.604 | |

| 10S | .109 | 2.157 | 2.638 | |||

| 40 | 40S Std. | .45 | 2.067 | 3.653 | ||

| 80 | 80S Ex. Hvy. | .218 | 1.939 | 5.022 | ||

| 160 | .344 | 1.689 | 7.462 | |||

| XX Hvy. | .436 | 1.503 | 9.029 | |||

| 2 ½ | 2.875 | 5S | .083 | 2.709 | 2.475 | |

| 10S | .120 | 2.635 | 3.531 | |||

| 40 | 40S Std. | .203 | 2.469 | 5.793 | ||

| 80 | 80S Ex. Hvy. | .276 | 2.323 | 7.661 | ||

| 160 | .375 | 2.125 | 10.01 | |||

| XX Hvy. | .552 | 1.771 | 13.69 | |||

| 3 | 3.500 | 5S | .083 | 3.334 | 3.029 | |

| 10S | .120 | 3.260 | 4.332 | |||

| 40 | 40S Std. | .216 | 3.068 | 7.576 | ||

| 80 | 80S Ex. Hvy. | .300 | 2.900 | 10.25 | ||

| 160 | .438 | 2.624 | 14.32 | |||

| XX Hvy. | .600 | 2.300 | 18.58 | |||

| 3 ½ | 4.000 | 5 | 5S | .083 | 3.834 | 3.472 |

| 10 | 10S | .120 | 3.760 | 4.973 | ||

| 40 | 40S Std. | .226 | 3.548 | 9.109 | ||

| 80 | 80S Ex. Hvy. | .318 | 3.364 | 12.50 | ||

| XX Hvy. | .636 | 2.728 | 22.85 |

| NOM.PIPE SIZE | OUTSIDE DIAM. INCHES | I.P.S. | SCHEDULE | WALL IN. | INSIDE DIAM. INCHES | WT/FT POUNDS |

| 4 | 4.500 | 5S | .083 | 4.334 | 3.915 | |

| 10S | .120 | 4.260 | 5.613 | |||

| 40 | 40S Std. | .237 | 4.026 | 10.79 | ||

| 80 | 80S Ex. Hvy. | .337 | 3.826 | 14.98 | ||

| 120 | .438 | 3.624 | 19.00 | |||

| 160 | .531 | 3.438 | 22.51 | |||

| XX Hvy. | .674 | 3.152 | 27.54 | |||

| 5 | 5.563 | 5S | .109 | 5.345 | 6.349 | |

| 10S | .134 | 5.295 | 7.770 | |||

| 40 | 40S Std. | .258 | 5.047 | 14.62 | ||

| 80 | 80S Ex. Hvy. | .375 | 4.813 | 20.78 | ||

| 120 | .500 | 4.563 | 27.04 | |||

| 160 | .625 | 4.313 | 32.96 | |||

| XX Hvy. | .750 | 4.063 | 38.55 | |||

| 6 | 6.625 | 5S | .109 | 6.407 | 7.585 | |

| 10S | .134 | 6.357 | 9.289 | |||

| 40 | 40S Std. | .280 | 6.065 | 18.97 | ||

| 80 | 80S Ex. Hvy. | .432 | 5.761 | 28.57 | ||

| 120 | .562 | 5.491 | 36.39 | |||

| 160 | .719 | 5.189 | 45.35 | |||

| XX Hvy. | .864 | 4.897 | 53.16 | |||

| 8 | 8.625 | 5S | .109 | 8.407 | 9.941 | |

| 10S | .148 | 8.329 | 13.40 | |||

| 20 | .250 | 8.125 | 22.36 | |||

| 30 | .277 | 8.071 | 24.70 | |||

| 40 | 40S Std. | .322 | 7.981 | 28.55 | ||

| 60 | .406 | 7.813 | 35.64 | |||

| 80 | 80S Ex. Hvy. | .500 | 7.625 | 43.39 | ||

| 100 | .594 | 7.439 | 50.95 | |||

| 120 | .719 | 7.189 | 60.71 | |||

| 140 | .812 | 7.001 | 67.76 | |||

| XX Hvy. | .875 | 6.875 | 72.42 | |||

| 160 | .906 | 6.813 | 74.69 | |||

| 10 | 10.750 | 5S | .134 | 10.482 | 15.19 | |

| 10S | .165 | 10.420 | 18.70 | |||

| 20 | .250 | 10.250 | 28.04 | |||

| 30 | .307 | 10.136 | 34.24 | |||

| 40 | 40S Std. | .365 | 10.020 | 40.48 | ||

| 60 | 80S Ex. Hvy. | .500 | 9.750 | 54.74 | ||

| 80 | .594 | 9.564 | 64.43 | |||

| 100 | .719 | 9.314 | 77.03 | |||

| 120 | .844 | 9.064 | 89.29 | |||

| 140 | 1.000 | 8.750 | 104.13 | |||

| 160 | 1.125 | 8.500 | 115.64 | |||

| 12 | 10.750 | 60 | .562 | 11.626 | 73.15 | |

| 80 | .688 | 11.376 | 88.63 | |||

| 100 | .844 | 11.064 | 107.32 | |||

| 120 | 1.000 | 10.750 | 125.49 | |||

| 140 | 1.125 | 10.500 | 139.67 | |||

| 160 | 1.312 | 10.126 | 160.27 | |||

| NOM.PIPE SIZE | OUTSIDE DIAM. INCHES | I.P.S. | SCHEDULE | WALL IN. | INSIDE DIAM. INCHES | WT/FT POUNDS |

| 14 | 14.000 | 10 | .250 | 13.500 | 36.71 | |

| 20 | .312 | 13.376 | 45.61 | |||

| 30 | Std. | .375 | 13.250 | 54.57 | ||

| 40 | .438 | 13.124 | 63.44 | |||

| Ex. Hvy. | .500 | 13.000 | 72.09 | |||

| 60 | .594 | 12.814 | 85.05 | |||

| 80 | .750 | 12.500 | 106.13 | |||

| 100 | .938 | 12.126 | 130.85 | |||

| 120 | 1.094 | 11.814 | 150.9 | |||

| 140 | 1.250 | 11.500 | 170.21 | |||

| 160 | 1.406 | 11.188 | 189.1 | |||

| 16 | 16.000 | 10 | .250 | 15.500 | 42.05 | |

| 20 | .312 | 15.376 | 52.27 | |||

| 30 | Std. | .375 | 15.250 | 62.58 | ||

| 40 | Ex. Hvy. | .500 | 15.000 | 82.77 | ||

| 60 | .656 | 14.688 | 107.5 | |||

| 80 | .844 | 14.314 | 136.61 | |||

| 100 | 1.031 | 13.938 | 164.82 | |||

| 120 | 1.219 | 13.564 | 192.43 | |||

| 140 | 1.438 | 13.124 | 223.64 | |||

| 160 | 1.594 | 12.814 | 245.25 | |||

| 18 | 18.000 | 10 | .250 | 17.500 | 47.39 | |

| 20 | .312 | 17.376 | 58.94 | |||

| Std. | .375 | 17.250 | 70.59 | |||

| 30 | .438 | 17.124 | 82.15 | |||

| Ex. Hvy. | .500 | 17.000 | 93.45 | |||

| 40 | .562 | 16.876 | 104.67 | |||

| 60 | .750 | 16.500 | 138.17 | |||

| 80 | .938 | 16.126 | 170.92 | |||

| 100 | 1.156 | 15.688 | 207.96 | |||

| 120 | 1.375 | 15.250 | 244.14 | |||

| 140 | 1.562 | 14.876 | 274.22 | |||

| 160 | 1.781 | 14.438 | 308.5 | |||

| 20 | 20.000 | 10 | .250 | 19.500 | 52.73 | |

| 20 | Std. | .375 | 19.250 | 78.60 | ||

| 30 | Ex. Hvy. | .500 | 19.000 | 104.18 | ||

| 40 | .594 | 18.814 | 123.11 | |||

| 60 | .812 | 18.376 | 166.4 | |||

| 80 | 1.031 | 17.938 | 208.87 | |||

| 100 | 1.281 | 17.438 | 256.1 | |||

| 120 | 1.500 | 17.000 | 296.37 | |||

| 140 | 1.750 | 16.500 | 341.09 | |||

| 160 | 1.969 | 16.064 | 379.17 | |||

| 22 | 22.000 | 10 | .250 | 21.500 | 58.07 | |

| 20 | Std. | .375 | 21.250 | 86.61 | ||

| 30 | Ex. Hvy. | .500 | 21.000 | 114.81 | ||

| 60 | .875 | 20.250 | 197.41 | |||

| 80 | 1.125 | 19.750 | 250.81 | |||

| 100 | 1.375 | 19.250 | 302.88 | |||

| 120 | 1.625 | 18.750 | 353.61 | |||

| 140 | 1.875 | 18.250 | 403.0 | |||

| 160 | 2.125 | 17.750 | 451.06 | |||

| 24 | 24.000 | 10 | .250 | 23.500 | 63.41 | |

| 20 | Std. | .375 | 23.250 | 94.62 | ||

| Ex. Hvy. | .500 | 23.000 | 125.49 | |||

| 30 | .562 | 22.876 | 140.68 | |||

| 40 | .688 | 22.626 | 171.29 | |||

| 60 | .969 | 22.064 | 238.35 | |||

| 80 | 1.219 | 21.564 | 296.58 | |||

| 100 | 1.531 | 20.938 | 367.39 | |||

| 120 | 1.812 | 20.376 | 429.39 | |||

| 140 | 2.062 | 19.876 | 483.1 | |||

| 160 | 2.344 | 19.314 | 542.13 |

Material Specifications – Fittings

| WALL THICKNESSES (Dimensions Common to Fittings and Pipe) | ||||||||||||||||

| NOM PIPE SIZE | OUTSIDE DIAM. | NOMINAL WALL THICKNESS (See Notes Below) | ||||||||||||||

| SCH. 5S† | SCH. 10S† | SCH. 10 | SCH. 20 | SCH. 30 | SCH. 40/S | SCH. 40 | SCH. 60 | SCH. 80/S | SCH. 80 | SCH. 100 | SCH. 120 | SCH. 140 | SCH. 160 | XX STRONG | ||

| 1/2 | 0.84 | 0.065 | 0.083 | 0.109 | 0.109 | 0.147 | 0.147 | 0.188 | 0.294 | |||||||

| 3/4 | 1.05 | 0.065 | 0.083 | 0.113 | 0.113 | 0.154 | 0.154 | -0.219 | 0.308 | |||||||

| 1 | 1.315 | 0.065 | 0.109 | 0.133 | 0.133 | 0.179 | 0.179 | 0.25 | 0.358 | |||||||

| 1 1/4 | 1.66 | 0.065 | 0.109 | 0.14 | 0.14 | 0.191 | 0.191 | 0.25 | 0.382 | |||||||

| 11/2 | 1.9 | 0.065 | 0.109 | 0.145 | 0.145 | 0.2 | 0.2 | 0.281 | 0.4 | |||||||

| 2 | 2.375 | 0.065 | 0.109 | 0.154 | 0.154 | 0.218 | 0.218 | 0.344 | 0.436 | |||||||

| 21/2 | 2.875 | 0.083 | 0.12 | 0.203 | 0.203 | 0.276 | 0.276 | 0.375 | 0.552 | |||||||

| 3 | 3.5 | 0.083 | 0.12 | 0.216 | 0.216 | 0.3 | 0.3 | 0.438 | 0.6 | |||||||

| 31/2 | 4 | 0.083 | 0.12 | 0.226 | 0.226 | 0.318 | 0.318 | 0.636 | ||||||||

| 4 | 4.5 | 0.083 | 0.12 | 0.237 | 0.237 | 0.337 | 0.337 | 0.438 | 0.531 | 0.674 | ||||||

| 5 | 5.563 | 0.109 | 0.134 | 0.258 | 0.258 | 0.375 | 0.375 | 0.5 | 0.625 | 0.75 | ||||||

| 6 | 6.625 | 0.109 | 0.134 | 0.28 | 0.28 | 0.432 | 0.432 | 0.562 | 0.719 | 0.864 | ||||||

| 8 | 8.625 | 0.109 | 0.148 | 0.25 | 0.277 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 | |

| 10 | 10.75 | 0.134 | 0.165 | 0.25 | 0.307 | 0.365 | 0.365 | 0.5 | 0.5 | 0.594 | 0.719 | 0.844 | 1 | 1.125 | ||

| 12 | 12.75 | 0.156 | 0.18 | 0.25 | 0.33 | 0.375 | 0.406 | 0.562 | 0.5 | 0.688 | 0.844 | 1 | 1.125 | 1.312 | ||

| 14 | 14 | 0.156 | 0.188 | 0.25 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.5 | 0.75 | 0.938 | 1.094 | 1.25 | 1.406 | |

| 16 | 16 | 0.165 | 0.188 | 0.25 | 0.312 | 0.375 | 0.375 | 0.5 | 0.656 | 0.5 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | |

| 18 | 18 | 0.165 | 0.188 | 0.25 | 0.312 | 0.438 | 0.375 | 0.562 | 0.75 | 0.5 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | |

| 20 | 20 | 0.188 | 0.218 | 0.25 | 0.375 | 0.5 | 0.375 | 0.594 | 0.812 | 0.5 | 1.031 | 1.281 | 1.5 | 1.75 | 1.969 | |

| 24 | 24 | 0.218 | 0.25 | 0.25 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.5 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | |

| 30 | 30 | 0.25 | 0.312 | 0.312 | 0.5 | 0.625 | 0.375 | 0.5 | ||||||||

Notes:

All dimensions are in inches – Prices on application.

Buttweld fittings are manufactured to ANSI B16.9 and B19.28 as applicable.

†Wall thicknesses shown for Schedules 5S and 10S in sizes thru 12” are as per ANSI B36.19. Wall thicknesses for 14” thru 30” are as tabulated in ASTM A 409.

* Wall thicknesses shown for Schedules 40S and 80S in sizes thru 12” are as per ANSI B36.19 and are the same as Standard Wall and Extra Strong per ANSI B36.10. Wall thicknesses for Schedules 40S and 80S, 14” thru 30” are not covered in ANSI B36.19 but are in accordance with the practice followed by industry, and in these sizes are also the same as Standard Wall and Extra Strong.